Trommel Screen

Contact Now

Products Details

Description

Trommel screen screens materials through rotating trommels and screens, and is suitable for handling all kinds of granular, massive or slurry materials.

Features

1)Sieve hole is not easy to block.

2) Smooth operation and low noise.

3) Simple structure and convenient maintenance.

4) The screening drum can be closed, which is easy to seal and collect dust.

Advantages

1.High-efficiency screening: the rotary screening method is adopted in the roller screen, and the materials are constantly tumbling and moving in the roller to realize continuous screening and improve production efficiency.

2.Strong adaptability: suitable for all kinds of materials, including ore, coal, sand and gravel, soil, garbage, biomass, etc., whether dry or wet.

3.Simple structure, convenient maintenance: simple structure, mainly composed of roller, driving device, bracket, easy to install and maintain.

Large capacity: able to process a large number of materials quickly.

Working Principle

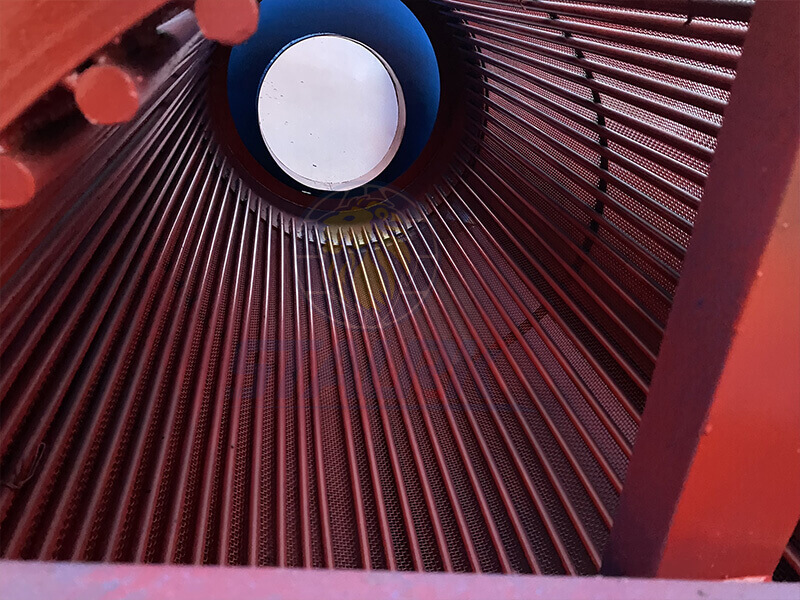

When the material enters the trommel device, due to the inclination and rotation of the trommel device, the material on the screen surface turns over and rolls, so that the qualified material (under-screen product) is discharged through the screen of the outer circle of the trommel, and the unqualified material (over-screen product) is discharged through the end of the trommel. Due to the turnover and rolling of materials in the trommel, the materials stuck in the sieve holes can be ejected to prevent the sieve holes from being blocked.

Application

The quarry is used for grading large and small stones and separating soil and stone powder, separation of sand and gravel from sand and gravel, the coal industry is used for separating lump coal from pulverized coal and washing coal,chemical industry and mineral processing industry are used to classify large and small blocks and separate powdery substances.

Technical Parameters

Model | Drum Diameter (mm) | Drum Length (mm) | Mesh Size (mm) | Power (kW) | Capacity (t/h) | Rotation Speed (rpm) | Inclination Angle (°) |

TS-600 | 600 | 1500 | 5-100 | 1.5-2.2 | 5-15 | 10-20 | 2-5 |

TS-800 | 800 | 2000 | 5-100 | 2.2-3.7 | 10-25 | 10-20 | 2-5 |

TS-1000 | 1000 | 2500 | 5-100 | 3.0-5.5 | 20-40 | 10-20 | 2-5 |

TS-1200 | 1200 | 3000 | 5-100 | 4.0-7.5 | 30-60 | 10-20 | 2-5 |

TS-1500 | 1500 | 4000 | 5-100 | 5.5-11.0 | 50-100 | 10-20 | 2-5 |

TS-1800 | 1800 | 5000 | 5-100 | 7.5-15.0 | 80-150 | 10-20 | 2-5 |