Rotary Dryer

Contact Now

Products Details

Description

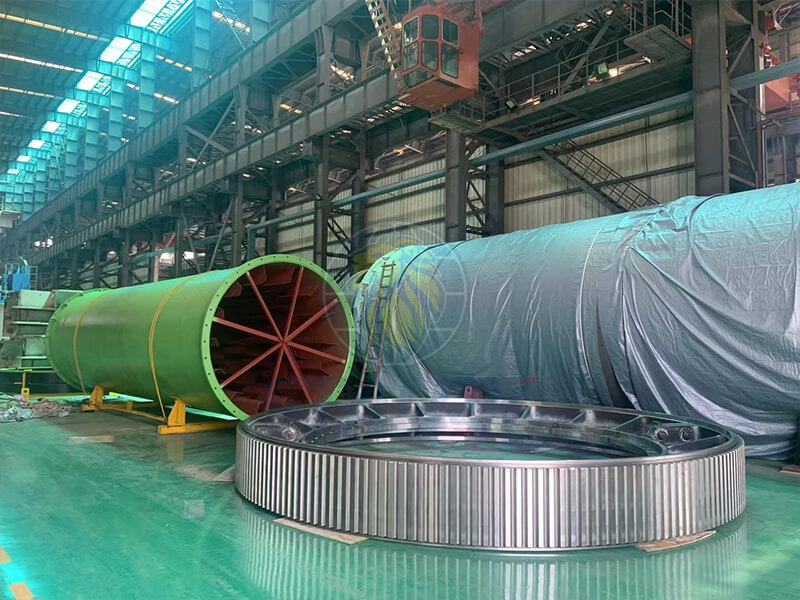

Rotary dryer is mainly composed of rotating body, lifting plate, transmission device, supporting device and sealing ring. Its new lifting plate device has many functions, such as guiding, equalizing flow, lifting materials, etc., which can make materials evenly distributed in the radial section of the dryer, completely contact with heat energy, and improve drying efficiency.

Features

1)Efficient drying: through hot air convection and material tumbling, the drying efficiency is high.

2)Large processing capacity: suitable for processing a large number of materials, suitable for industrial production..

3)Strong adaptability: can handle a variety of materials, such as particles, powder, blocks and so on.

4)Temperature controllable: the drying process is controlled by adjusting the temperature and flow of hot air.

Advantages

1. Large processing capacity, suitable for continuous operation.

2. High drying efficiency and low energy consumption.

3. The structure is firm and the maintenance cost is low.

4. Different heating methods can be selected according to the material characteristics.

Working Principle

Wet materials enter the cylinder of rotary dryer through the feed inlet. Hot air or hot gas enters from one end of the cylinder and directly or indirectly contacts with the material. The cylinder rotates at a certain speed, so that the materials keep rolling in the cylinder and fully contact with the hot air, and the water gradually evaporates. The dried material is discharged from the other end of the cylinder. Waste gas containing water vapor is discharged after being treated by dust removal equipment.

Application

Rotary dryer is widely used in mining, cement, chemical industry and other industries. For example, it is suitable for drying metallic and nonmetallic minerals, clay, coal slime and other materials.

Technical Parameters

Model | Diameter (m) | Length (m) | Capacity (TPH) | Power (kW) | Rotation Speed (rpm) | Inlet Temperature (°C) | Application |

RD-1.2×10 | 1.2 | 10 | 5-10 | 7.5 | 3-8 | 150-300 | Drying sand, clay, and minerals |

RD-1.5×15 | 1.5 | 15 | 10-20 | 11 | 3-8 | 150-300 | Drying coal and slag |

RD-2.0×20 | 2.0 | 20 | 20-40 | 18.5 | 3-8 | 150-300 | Drying biomass and sawdust |

RD-2.5×25 | 2.5 | 25 | 40-60 | 22 | 3-8 | 150-300 | Drying fertilizers and chemicals |

RD-3.0×30 | 3.0 | 30 | 60-100 | 37 | 3-8 | 150-300 | Large-scale industrial drying |